Introduksjon:

This machine including one set ZL520 vertical bag making packing and sealing machine .one set ZL2000 Auger measuring machine ,One set ZL100V2 double vacuum chamber packing machine ,and one set output conveyor .The machine have the function of bag forming ,product filling ,bag cleaning and vacuuming .Can choose thermal transfer coding machine which are more popular for make date coding on Coffee brick vacuum bag .This machine are widely use for packing food pharmacy chemical and other product in powder or small granule. Like coffee powder ,yeast powder wheat flour and so on .The whole machine adopting inside pumping to vacuum product .The vacuum degree is very high and packing speed is very high can be reach 8bag/min .The finished product is very nice and have a long shelf life.

Application :

Tekniske parametere :

Model :ZL100V2 ( Double vacuum chamber )

Packing speed :200-250gram 25-30bag/min

500gram 22-25bag/min

Maskindimensjon: 6800*3800*4080mm

Power :18kw(Suggest client use air storage tank with volume is 1.5cbm)

ZL100V2 LINEÆR TYPE DOBBELT STØVSUG KAMMER PAKKEMASKIN

This machine is special design for vacuum packing product in high vacuum degree .The whole machine is control by Siemens PLC and touch screen .Adopt famous brand Pneumatic Components. Start the Vacuum process in vacuum chamber can reach the high vacuum degree.

Teknisk parameter:

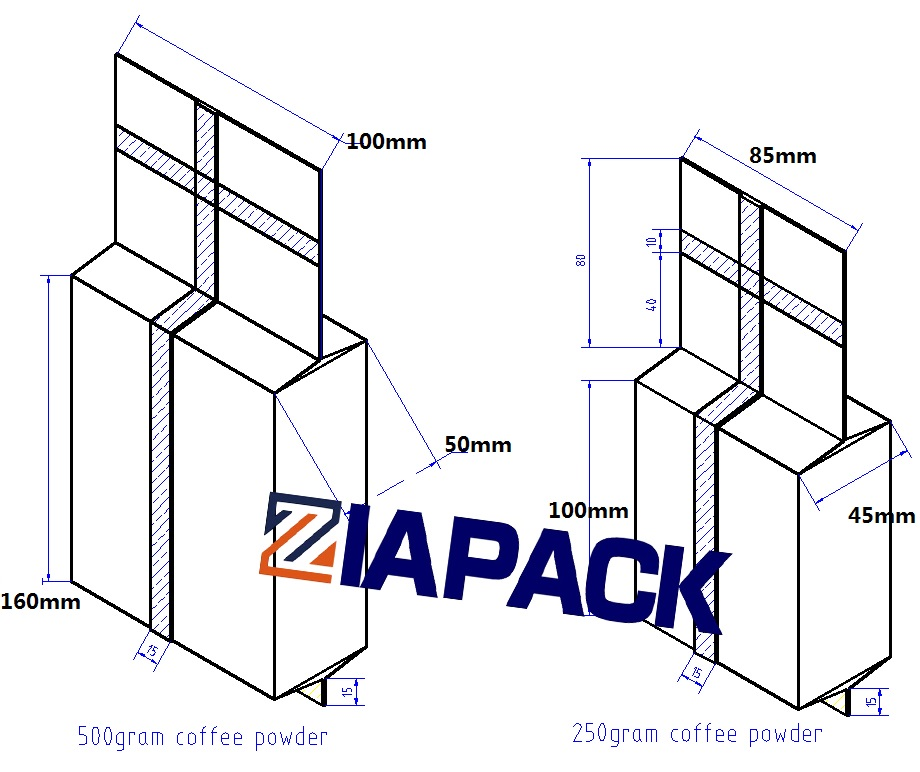

Veskelengde: 100-260mm

Posebredde: 60-250 mm (sidebredde + frontbredde)

Posetype: Vakuumpose av murstein

Luftkildeforbruk: 0,6 MPa 0,45 m3/min

Effekt: 8KW 380V±10% 50Hz

Maskinvekt: 1200 kg

Working progress :

Get gusseted bag from VFFS packaging machine (bag mouth opening )---forming &opening the bag mouth ---Filling the material from auger filler---Cleaning the bag mouth and vibrating ----Press module to pressing the bag material ---Folding the gusseted with vibrating ---Folding the top to make the top flat ----send to vacuum chamber ---Pushing into vacuum chamber ----Vacuuming and heating sealing --- Output from vacuum chamber ---Send to cutting the bag top area .---Finished bag output